If you are in need of a plastic pallet mould, then you should consider the Three Skid Injection Pallet Mould. It has a flat top surface and a reinforced structure with ribs at the base. The ribs are usually three millimetres thick. The thickness of the ribs can be adjusted according to the injection moulding draft angle. The ratio of the flow length and rib thickness should not exceed 150. This ratio is sufficient to keep the melting state of the polymer.

When designing a three-skid injection pallet mould, it is important to take into account the effects of temperature on the properties of the product. The temperature of the mould cavity and the core is not the same during the entire process. The same thing holds true for mould opening and closing times. If the temperature of the mould is not controlled, then the material will be unstable during the process.

The injection-mould process has a number of advantages. First, the moulding process is quicker and easier. The process is also more accurate. This process ensures a high-quality product. Injection-moulded skids last a long time. This process also makes the assembly process easier, because fewer parts are needed.

The process begins by filling the mould cavity with plastic. After this process, the injection inlet is closed. A cooling period of four to ten seconds follows. During this time, the movable insert 105 is forced to move further into the mould cavity. This causes the plastic to compress and expand towards the core, which is the densest area of the moulded product.

The two main parts of the three-skid pallet mould are the upper deck and the slats. The upper deck 2 is formed by injection moulding. It has longitudinal slats foura to c and transverse slats five. Injection moulding also creates three skids of equal length and width. This makes pallet 30 possible.

A third important feature of the three-skid injection pallet mould is its ability to predict the flatness of the pallet. The accuracy of the predictor depends on the accuracy of the ATOS. The ATOS of the bottom side of the three-skid pallet should be within 0.7 mm. Moreover, the bottom side of the pallet should be flat.

The simulated and measured heights of the pallet are closely matched. The measured height of the middle profile (yc) was only 0.92 mm higher than the calculated one. The deformations of the middle profile (yc) along the y-axis are also small compared to the measured ones.

The flatness of the pallet has two characteristics - the cold side is softer and stiffer than the hot side. The hot side of the pallet experiences more cooling than the cold side, which results in warpage towards the cold side.

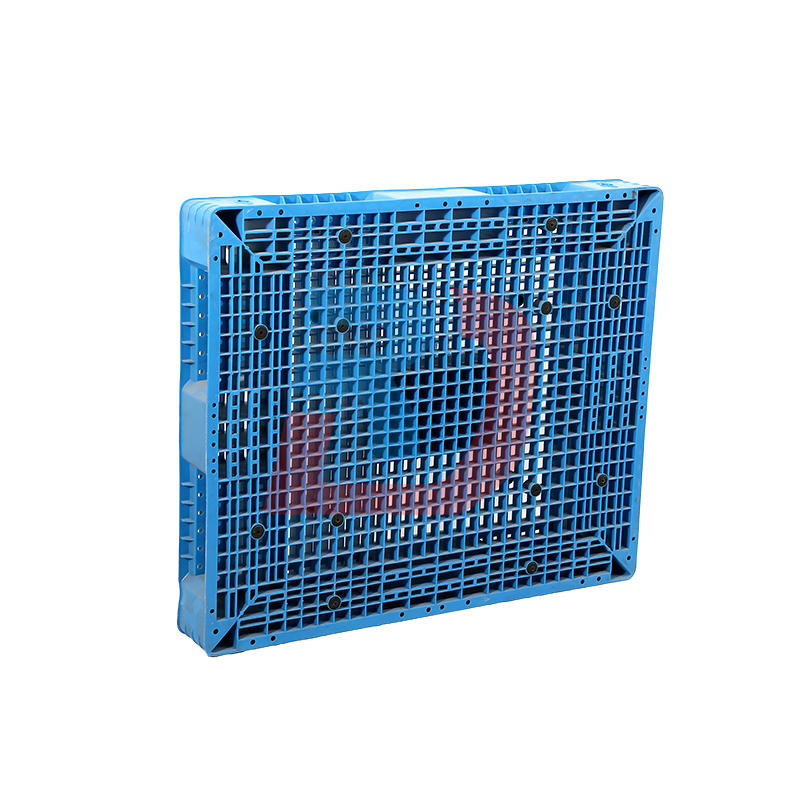

1210 PALLET MOULD GRID DOUBLE-DECK TYPE PALLET

Parameter: 1200*1000*150mm Grid Double-deck type Pallet

English

English Español

Español 中文简体

中文简体